Integrations

Integrations

Streamlining Service Operations for Messer Cutting Systems with Salesforce

Infor LN ERP Integration

Infor LN ERP Integration

WhatsApp Integration

WhatsApp Integration

Products

Products

Service Cloud

Service Cloud

Field Service Lightning

Field Service Lightning

Customer Community

Customer Community

WatBox

WatBox

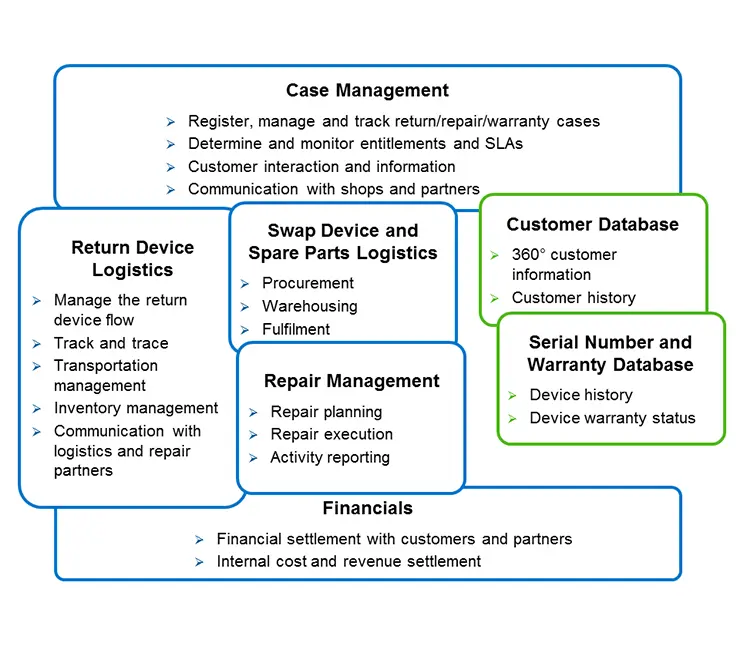

Overview

Messer Cutting Systems India, a subsidiary of the global Messer Group, is a leading manufacturer of high-performance cutting machines tailored for the metal-working and fabrication industry. With over 1500 active customers, Messer offers a wide range of cutting machines and software solutions for gas, plasma, laser, and oxyfuel cutting processes, along with comprehensive service and support.

Problem Statement

Messer Cutting Systems faced several operational challenges that hindered service efficiency and revenue generation:

- Service Downtime: Quick resolution of machine breakdowns is critical to minimize downtime and ensure smooth operations. Delays in service operations were leading to significant revenue losses for customers.

- Revenue Leakage: The company’s revenue model relied heavily on service costs, annual maintenance contracts (AMCs), spare parts sales, and retrofits. Manual service operations created inefficiencies, resulting in revenue leakage and the inability to forecast service-related income accurately.

- Customer Retention: Competitors were capturing market share by offering better service and consumables, leading to lost opportunities for retaining existing customers.

- Operational Visibility: As a service head, tracking technician availability and predicting resource requirements across multiple territories was challenging, given the large number of customers, machines, and service tickets.

- Technician Efficiency: Technicians struggled to access relevant data while on the field, such as customer information, asset details, machine history, AMC details, warranty status, and spare parts availability.

Solution

- Key Customer Management: Customers were classified based on their machine count, AMC contracts, and service priority. Additionally, we enabled customers to raise service tickets via WhatsApp, phone calls, the customer portal, and the website, simplifying ticket submission.

- Centralized Service Requests: All service requests from various channels (phone, email, WhatsApp, SMS, and customer portal) were consolidated into the Salesforce Service Cloud platform for better management and tracking.

- Efficient Resource Allocation: Automated resource allocation based on technician skills, preferred regions, and availability. This saved time and improved ticket assignment accuracy.

- Mobile Access for Technicians: Technicians were equipped with the Field Service Mobile app, providing them with a 360-degree view of customer information, machine details, AMC, warranty data, spare parts availability, and service costs. This enhanced data accessibility, enabling quicker problem resolution in the field.

- Knowledge Base & Troubleshooting: We implemented troubleshooting guidelines using Salesforce Knowledge articles, allowing technicians to find solutions faster.

- Knowledge Base & Troubleshooting: We implemented troubleshooting guidelines using Salesforce Knowledge articles, allowing technicians to find solutions faster.

- Service Contract Management: Service contracts were configured to manage machine warranties, including service resource costs, travel costs, and AMC renewals. This helped prevent revenue leakage by automating renewals and contract management.

- Seamless Integration with Infor LN ERP: The system was integrated with Infor LN ERP to streamline data exchange between the ERP and CRM. Key actions included:

- Passing machine details from the ERP to CRM when a machine is dispatched.

- Sending service invoices and related information from the CRM to the accounting department after service completion.

- Predictive Analytics: We configured analytics to predict resource needs and optimize technician allocation based on the volume of service tickets in each territory.

- Comprehensive Service Management: The solution provided end-to-end management for:

- Pre-installation and installation Management

- Service cost and spare parts management

- Predictive maintenance

- Frequent failure analysis and management

- Retrofit services

Result

- Improved Customer Satisfaction: With multiple service request channels and better collaboration among technicians, customer satisfaction scores increased to 80%.

- Revenue Growth: The automated system eliminated revenue leakage, resulting in a 15% increase in service operations revenue.

- Efficiency Gains: The reduced case resolution time led to lower manpower costs and improved technician utilization.

- Full Operational Visibility: Management gained real-time visibility into service operations, leading to better decision-making and optimized business performance.

By implementing Salesforce Service Cloud, Field Service Lightning, and several integrations, Messer Cutting Systems India has streamlined its service operations, minimized revenue leakage, and significantly improved both customer satisfaction and service revenue.

.

.